Ti-Ta-W-based cemented carbides for cutting tool applications

Description

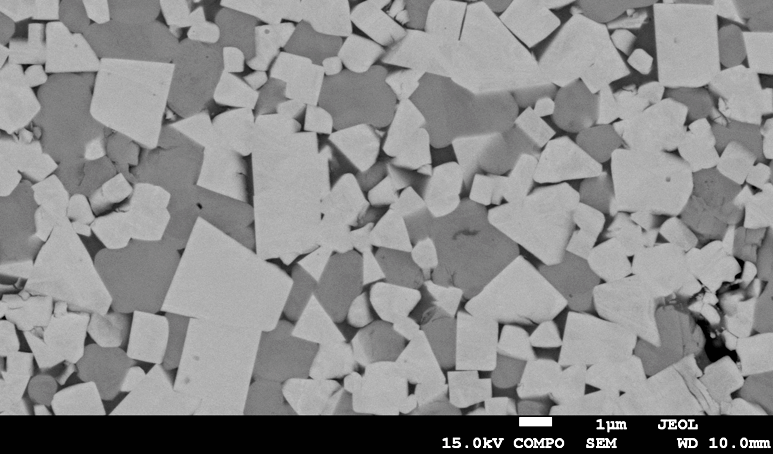

Ti-Ta-W-based cemented carbides (TTC) for multi-purpose cutting insert applications are sintered three-phase materials based on carbides of W, Ti and Ta embedded in Co binder, typically processed by powder metallurgy route. Metallic binder content typically varies from 6 wt% to 11 wt%. Unlike conventional two-phase WC-based hard metals, TTC materials contain nearly spherical grains of solid solution Ti-Ta-W phase, WC grains, and Co-rich phase which is basically a solid solution of three carbides in cobalt.

TTC cemented carbides have high hardness, superior hot strength, good oxidation and abrasion resistance, and improved hot hardness. They also have high toughness, wear-resistance and very good cutting edge strength when used as cutting tools.

Applications

![]() Structural steel

Structural steel

![]() Low-alloyed steel

Low-alloyed steel

![]() Stainless steel

Stainless steel

![]() Grey, malleable, high-strength cast iron grades

Grey, malleable, high-strength cast iron grades

| Parameter | Material | |||

| VHS55 | VHS60 | VHS65 | VHS58 | |

| Chemical analysis, wt% | WC–74, TiC-15, TaC-5, Co-6 | - | WC–74, TiC-8, TaC-7, Co-11 | - |

| Density,g/cm³ | 13.1 | 12.5 | 13.3 | 13.2 |

| Microstructure, micron

| 1 - 2 | 1 - 2 | 1 - 2 | 1 - 2 |

| Coercitivity, Oe | 145 - 175 | 120 - 170 | 145 - 175 | - |

| Transverse rupture strength, MPa | 2000 | 1500 | 2300 | 1520 |

| Rockwell hardness, HRA | 91.5 | 91.0 | 90.0 | 91.3 |

| Impact toughness, kJ mˆ(-2) | 18 - 20 | - | 20 - 25 | - |

| Fracture toughness, MPa m½ | - | 8.0 - 9.0 | - | 8.0 - 10.0 |